Balancing Precision and Cost in Modern Metal Bending

Introduction

In today’s competitive manufacturing environment, metal fabrication companies are under constant pressure to deliver high-quality products while keeping operational expenses low. This challenge has driven strong interest in the affordable CNC press brake industry, where innovation is focused on achieving accuracy, efficiency, and reliability without excessive investment.

Affordable solutions are no longer basic or limited. Modern CNC press brakes now incorporate advanced control systems, energy-efficient designs, and flexible configurations that were once available only in premium machines. For small and medium-sized workshops, these developments are transforming how bending operations are planned, executed, and scaled.

The Evolution of Affordable CNC Press Brakes

CNC press brakes have evolved significantly over the past two decades. Early models emphasized automation and repeatability but came with high costs and complex maintenance requirements. As technology matured, manufacturers began refining designs to reduce unnecessary complexity while preserving core performance features.

Affordable CNC press brakes today are the result of this evolution. They focus on essential capabilities such as precise ram control, press brakes hybrid press brakes and reliable hydraulic or hybrid systems. This approach allows fabricators to achieve consistent results without investing in overly sophisticated machinery that may not suit their production volume.

Why Affordability Matters in Fabrication

Affordability in manufacturing equipment is not just about the purchase price. It includes energy consumption, maintenance costs, operator training, and long-term reliability. For many businesses, especially job shops and regional fabricators, controlling these factors determines profitability.

An affordable CNC press brake enables companies to modernize their operations while maintaining financial stability. Instead of relying on manual bending or outdated machines, workshops can adopt CNC technology that improves accuracy and reduces waste. Over time, the savings generated through improved efficiency often outweigh the initial investment.

Energy Efficiency and Hybrid Technology

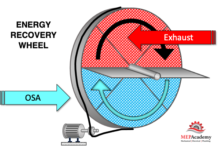

Energy consumption is a major concern in bending operations, particularly for businesses running multiple shifts. This has led to growing interest in systems that reduce power usage without sacrificing performance. In this context, press brakes hybrid press brakes have gained attention for their balanced approach.

Hybrid designs combine hydraulic power with electric servo technology. This allows the machine to consume energy only when movement is required, rather than running continuously. The result is lower electricity costs, reduced heat generation, and more stable bending performance. For cost-conscious manufacturers, these benefits directly support affordability goals.

Performance Without Compromise

One common misconception is that affordable machines compromise on quality. In reality, modern CNC press brakes are designed to deliver precise and repeatable bends across a wide range of materials. From thin aluminum sheets to thicker steel plates, these machines provide consistent results when properly configured.

Hybrid systems further enhance performance by offering smoother ram movement and finer control. This is especially important for complex bends or parts with tight tolerances. By maintaining accuracy while reducing energy usage, these machines demonstrate that affordability and performance can coexist.

See also: Cyrillic Fonts: Tradition, Technology, and Typography

Versatility for Diverse Production Needs

Fabrication shops rarely produce a single type of component. Most handle a mix of custom orders, small batches, and repeat production runs. Affordable CNC press brakes are well suited to this environment because they offer flexibility in tooling, programming, and setup.

With user-friendly CNC controls, operators can quickly switch between jobs and adjust parameters as needed. Hybrid systems support this versatility by delivering consistent force and speed control, making it easier to handle varied bending requirements without extensive manual intervention.

Simplified Operation and Training

Labor availability is another challenge facing the fabrication industry. Skilled press brake operators are in high demand, and training new staff can be time-consuming. Affordable CNC press brakes address this issue through intuitive control interfaces and automated features.

Graphical programming, stored bending sequences, and real-time feedback help operators learn faster and make fewer errors. Hybrid machines often add to this advantage by operating more quietly and smoothly, creating a better working environment that supports productivity and safety.

Maintenance and Long-Term Value

Maintenance costs play a critical role in determining the true affordability of a press brake. Machines that require frequent servicing or specialized parts can quickly become expensive to own. Affordable CNC press brakes are typically engineered with simplicity and durability in mind.

Hybrid technology contributes to long-term value by reducing wear on hydraulic components. Lower operating temperatures and optimized power usage extend the lifespan of critical parts. For shop owners, this means fewer breakdowns, predictable maintenance schedules, and lower overall operating costs.

Real-World Benefits for Small and Medium Shops

Consider a mid-sized fabrication shop producing enclosures and structural components. Before upgrading, the shop relied on older hydraulic equipment that consumed large amounts of energy and required frequent adjustments. Production was slow, and quality varied between operators.

After investing in an affordable CNC press brake with hybrid features, the shop experienced immediate improvements. Energy costs dropped, setup times were reduced, and product consistency improved. Over time, these gains allowed the business to take on more orders and compete with larger manufacturers.

Supporting Sustainable Manufacturing

Sustainability is becoming an increasingly important factor in manufacturing decisions. Customers and partners are paying closer attention to how products are made, including energy usage and environmental impact. Affordable CNC press brakes with energy-efficient designs support these expectations.

Hybrid systems, in particular, align well with sustainability goals. By reducing power consumption and minimizing waste, they help businesses operate more responsibly while also saving money. This combination of economic and environmental benefits strengthens a company’s market position.

The Future of Affordable CNC Press Brake Technology

The future of the affordable CNC press brake industry is closely tied to ongoing innovation. Advances in software integration, adaptive bending systems, and remote monitoring are becoming more accessible to smaller manufacturers. Hybrid technology is expected to play a central role in this progress.

As these features become standard rather than optional, affordable machines will continue to close the gap with high-end equipment. For fabricators, this means greater access to advanced capabilities without the burden of excessive costs.

Conclusion

The affordable CNC press brake industry has reached a point where cost efficiency and high performance are no longer opposing goals. Through smart design, energy-efficient systems, and user-focused controls, modern machines deliver reliable bending solutions for a wide range of applications.

The growing adoption of press brakes hybrid press brakes highlights the industry’s commitment to balancing precision, sustainability, and affordability. For fabrication businesses looking to modernize without overextending financially, these machines offer a practical path forward. In an industry defined by precision and efficiency, affordable CNC press brakes are proving that smart investment leads to lasting value.